Hunhu hweFRP mold hunoenderana zvakananga nekuita kwechigadzirwa, kunyanya maererano nedeformation rate, durability, nezvimwe, izvo zvinofanirwa kudiwa kutanga.Kana iwe usingazivi maitiro ekuona kunaka kwe mold, saka tapota verenga mamwe mazano munyaya ino.

1. Kuongororwa kwepamusoro kwemuumbi kunoitwa kana yasvika, uye inotarisirwa kuti parege kuva nemuenzaniso wejira rinooneka pamusoro;

2. Kuwanda kwejasi rejasi rekuumbwa kwakakura kudarika kana kuenzana ne 0.8mm, uye hupamhi hwejasi rejeri ndiyo hupamhi hwejeri rejasi mushure mekuporesa uye kuumba, kwete hupamhi hwefirimu yemvura;

3. Panofanira kunge pasina resin deposition pamusoro pekona ye mold.

4. Muviri mukuru wekuumbwa, kureva, kupisa kwekushisa kwekushisa kweFRP laminate, maererano ne2001 resin parameter ≥110℃.

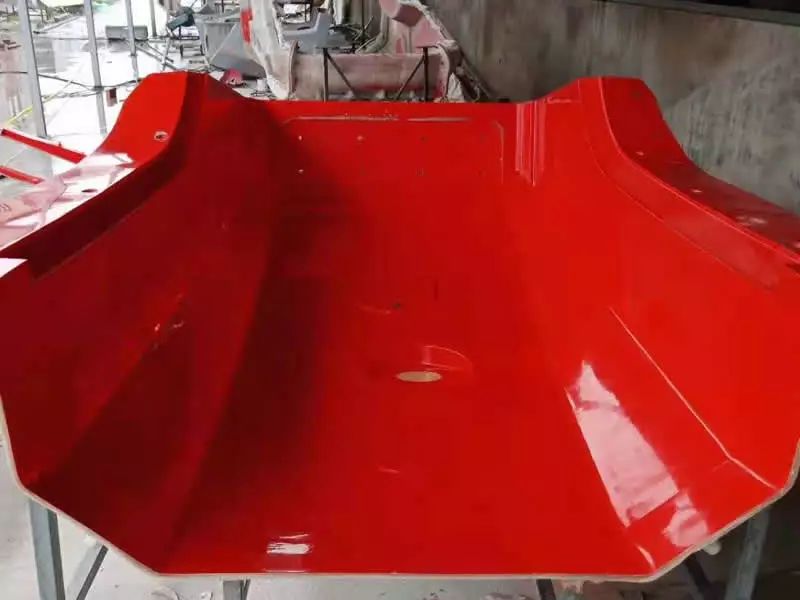

5. Kubwinya uye kupenya kwepamusoro pejasi rejeli kunodiwa kuti usvike paA-level surface.Kune iyo yakatwasuka ndege, iyo silhouette inogona kuratidzwa zvakajeka pasina deformation.

6. Kuomarara kwepamusoro zvinodiwa zvejasi rejeli: avhareji kukosha kwekuomarara kwebhazi yegumi ekupararira mapoinzi akayerwa nemuviri wekuumbwa yakakura kupfuura makumi matatu neshanu.

7. Mamiriro epamusoro emuumbi haadi mabhubhu pamusoro pevhu, kwete kupfuura 3 mabhubhu mukati me 1m2 yemabhuru anooneka mujasi regel uye mold laminate;hapana mavara akajeka ebhurashi, zvikweshwa uye mavanga ekugadzirisa pamusoro peiyo mold, uye hapana anopfuura mashanu pinholes mukati me1m2 yepasi.A, hapagoni kuva nechiitiko chekuisa.

8. Chigadziko chesimbi chemuumbi chinonzwisisika, uye chinofanira kunge chine chimiro chepamusoro.Iyo clamping papuratifomu inofanirwa kuve yakasimba uye isiri nyore kuremara;iyo hydraulic device inovhura uye inovhara zvakanaka uye zvakanaka, kukurumidza kunogadziriswa, uye shanduko yekufamba inopiwa, iyo inogona kusangana nekuzarura nekuvhara nguva> 1000 nguva mukushandiswa kwakajairika.

9. Iyo mold yakagadzirwa maererano neyakagadzirwa vacuum process, ukobvu hwemuviri mukuru hunodiwa kusvika 15mm, uye hupamhi hweflange yemuumbi hunodiwa kuve ≥18mm.

10. Mapini ekumisikidza e mold mapini esimbi, uye mapini uye zvikamu zveFRP zvinofanirwa kuvharwa.

11. Mutsara wekucheka we mold unonyatsoongororwa maererano nehuwandu hwechigadzirwa.

12. Kuenzana kwehukuru hwehutu hunoda kuve hwakarurama, uye kukanganisa kwekuenzanisa pakati pezvikamu zvinofanirwa kunofanira kuva ≤1.5mm.

13. Hupenyu hwese hwese hwechiumbwa hahufanire kunge huri pasi pe500 seti yezvigadzirwa.

14. The flatness of the mold is ± 0.5mm per linear mita, uye hapafaniri kuva nekusaenzana.

15. Zvose zviyero zvemuumbi zvinovimbiswa kuva nekukanganisa kwe ± 1mm, uye hapana burr pamusoro pe laminate.

16. Kumusoro kwechiumbwa hachibvumirwi kuva nekuremara kwakadai semapini, orange peel mapatani, sandpaper scratches, huku tsoka kuputika, nezvimwewo, uye arc inofanira kunge yakanyatsochinja.

17. Iyo mold inoporeswa mushure mekupisa kwepamusoro kwe80 ° C, uye yakaderedzwa mushure memaawa masere.

18. Iyo mold haigone kukanganiswa pasi peiyo exothermic peak mamiriro e90 ℃-120 ℃, uye pamusoro haigone kuoneka shrinkage mamaki, makatsemuka, uye kusaenzana.

19. Panofanira kuva nemukaha weinopfuura 10mm pakati pesimbi yesimbi uye mold, uye kubatanidzwa kwemitumbi miviri inofanira kuputirwa nekork kana mapuranga akawanda ehupamhi hwakafanana.

20. Kubatana kwechikamu chekuparadzanisa hakugoni kubviswa, chimiro chekugadzirisa chimiro chinonzwisisika, mold inosunungurwa, kushandiswa kwechigadzirwa kuri nyore, uye mold iri nyore kusunungura.

21. Zvose zvakashata zvakashata zvemuumbi zviri pasi pe 0.1, uye kudzvinyirira kunochengetwa kwemaminitsi mashanu.

Nguva yekutumira: Mar-22-2022