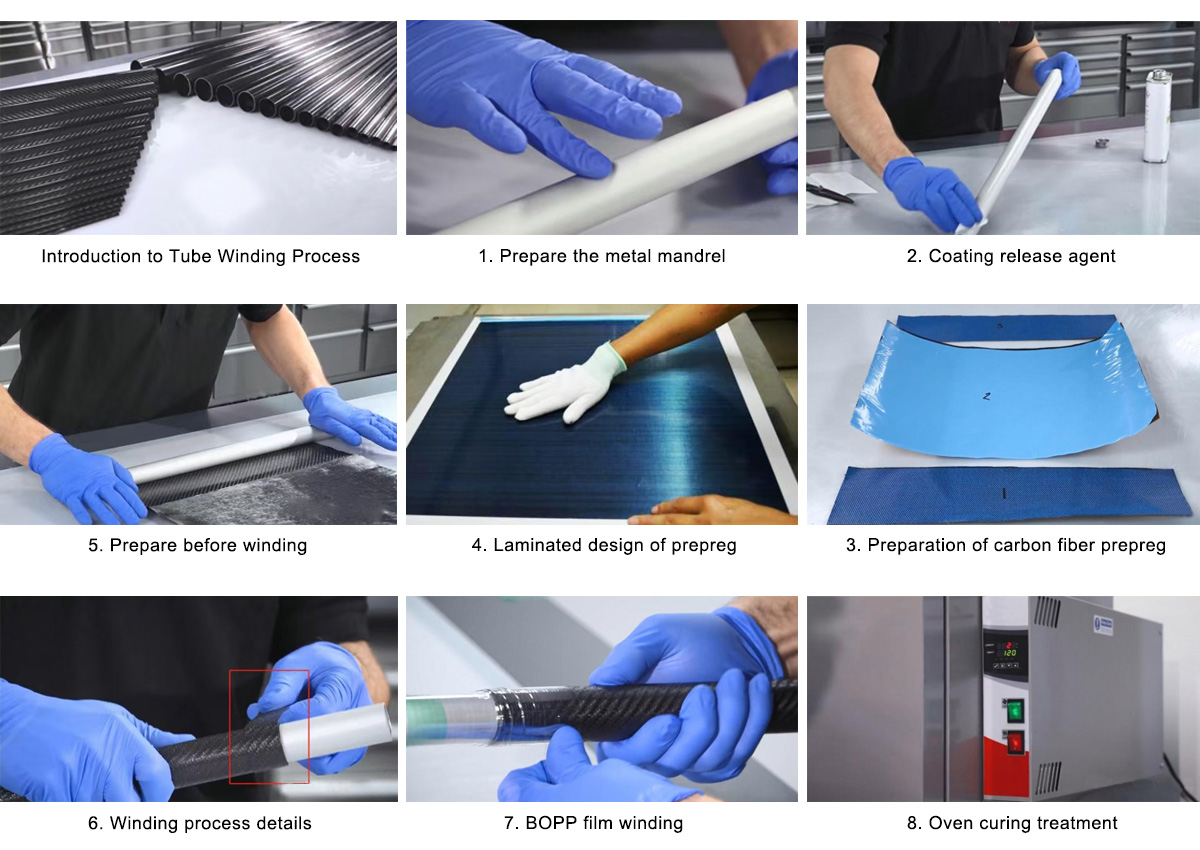

1. Nhanganyaya yeMaitiro Ekupeta Tube

Kuburikidza nedzidziso iyi, uchadzidza mashandisiro aungaita maitiro ekumonera machubhu kugadzira zvivakwa zvemachubhu uchishandisa carbon fiber prepregs pamuchina wekumonera machubhu, nokudaro uchigadzira simba rakasimba.machubhu ekabhoni faibhaMaitiro aya anowanzo shandiswa nevagadziri vezvinhu zvakasanganiswa.

Kana uchida kugadzira machubhu ane mativi akafanana kana kuti anochinjika nguva dzose, nzira yekumonera machubhu ndiyo sarudzo yakanaka. Chaunongoda isimbi ine saizi yakakodzera uye ovheni yekugadzira machubhu ecarbon fiber akagadzirirwa zvaunoda.

Kune machubhu ecarbon fiber akaita seakaomarara, akadai sema handlebars kana ma truble frame structures akaomarara akadai se suspension forks kana mabhasikoro frames, split-mold technology ndiyo nzira inonyanya kufarirwa. Iye zvino ticharatidza mashandisirwo e split-mold technology kugadzira machubhu aya akaomarara ecarbon fiber.

2. Kugadziriswa uye Kugadzirwa kweMandrels esimbi

- Kukosha kweMandrel eSimbi

Usati watanga maitiro ekumonera machubhu, danho rekutanga kugadzirira ma mandrel esimbi. Ma mandrel esimbi anofanira kuenderana nedhayamita yemukati memachubhu, uye kutsvedzerera kwawo pamusoro uye kugadziriswa kwakakodzera kwakakosha. Pamusoro pezvo, ma mandrel esimbi anofanira kugadziriswa zvakanaka, sekucheneswa nekushandisa chinhu chinosunungura, kuti zvive nyore kubvisa machubhu.

Munguva yekumonera chubhu, simbi yesimbi inoita basa rakakosha sezvo inofanira kutsigirakugadzirira kabhoni fiberkuti ive nechokwadi chekuti mandrel inomonereka zvakanaka. Saka, kugadzirira saizi yakakodzera yesimbi pachine nguva kwakakosha. Sezvo kabhoni fiber ichamonererwa pamusoro pekunze kwe mandrel, dhayamita yekunze ye mandrel inofanira kuenderana nedhayamita yemukati yechubhu yekabhoni fiber ichagadzirwa.

- Kushandisa mumiririri wekusunungura

Zvinosunungura zvinoderedza kukweshana uye zvinoita kuti zvibviswe zvakanaka; zvinofanirwa kuiswa zvakaenzana pamusoro pemandrel. Mushure mekunge mandrel yesimbi yagadzirwa, danho rinotevera nderekuisa chinosunungura. Zvinosunungura zvinowanzo shandiswa zvinosanganisira silicone oil neparafini, izvo zvinoderedza kukweshana pakati pecarbon fiber nemetal mandrel.

Pamandrel esimbi akagadzirwa, tinofanira kuva nechokwadi chekuti akachena zvakakwana uye pamusoro pawo pakanyatsotsvedzerera kuitira kuti chigadzirwa chibviswe zvakanaka. Zvadaro, chinhu chinosunungura chinofanira kuiswa zvakaenzana pamusoro pemandrel.

3. Kugadzirira carbon fiber prepreg

- Mhando uye zvakanakira zve prepreg

Magadzirirwo e carbon fiber chete ndiwo anosangana nezvinodiwa zvepamusoro zvekunyatso tenderera uye nyore kubata. Kunyangwe mamwe marudzi ezvinhu zvinosimbisa, zvakaita semachira akaoma akaiswa epoxy, anogona kushandiswa mukuita kwekumonera, mukuita, magadzirirwo e carbon fiber chete ndiwo anogona kusangana nezvinodiwa zvepamusoro zvekunyatso tenderera uye nyore kubata mukuita uku.

Muchidzidzo chino, tinoshandisa nzira chaiyo yekugadzirira madziro kuti tiwedzere kushanda kwemachubhu.

- Dhizaini yekugadzirira Layup

Rutivi rwe prepreg yakarukwa runoiswa mukati mechubhu, rwuchiteverwa nezvikamu zvakati wandei zve prepreg yakarukwa, uye pakupedzisira rumwe rutivi rwe prepreg yakarukwa runoiswa kunze kwechubhu. Dhizaini iyi inoshandisa zvizere mabhenefiti e fiber orientation e woven prepreg pa 0° ne 90° axes, zvichiwedzera zvakanyanya mashandiro echubhu. Ruzhinji rwe prepreg dzakarukwa dzakaiswa pa 0° axis dzinopa kuomarara kwakanaka kwe longitudinal kuchubhu.

4. Kuyerera kwenzira yekutenderera kwepombi

- Kugadzirira kuputira

Mushure mekupedza dhizaini ye prepreg layup, maitiro acho anoenderera mberi nemaitiro ekumonera pombi. Kugadzira prepreg kunosanganisira kubvisa firimu rePE nepepa rekuburitsa, uye kuchengetedza nzvimbo dzakakodzera dzinopindirana. Danho iri rakakosha pakuona kuti maitiro ekumonera anotevera anofamba zvakanaka.

- Tsanangudzo yemaitiro ekumonera

Munguva yekumonera, zvakakosha kuve nechokwadi chekuti prepregs dzakamonera zvakanaka, simbi yakagadzikwa zvakanaka uye simba rakashandiswa zvakaenzana. Metal core shaft inofanira kuiswa zvakanaka pamucheto wechikamu chekutanga che prepregs, zvichiita kuti simba rishande zvakaenzana.

Munguva yekumonera, mamwe ma prepregs anogona kupwanywa kumagumo kuitira kuti chigadzirwa chibviswe panguva yekumonera.

- Kuputira Firimu reBOPP

Pamusoro pe prepreg, firimu reBOPP rinogona kushandiswawo pakuputira. Firimu reBOPP rinowedzera kumanikidzwa kwekubatanidza, rinodzivirira, uye rinovhara prepreg. Pakushandisa firimu rekuputira reBOPP, zvakakosha kuve nechokwadi chekuti matepi acho anowirirana zvakakwana.

5. Maitiro Ekuchenesa Ovheni

- Kupisa Tembiricha uye Nguva

Mushure mekuputira zvakasimba chinhu chakasimbiswa ne prepreg carbon fiber, chinotumirwa kuovheni kuti chigayiwe. Kudzora tembiricha kwakakosha panguva yekugayiwa muovheni, sezvo ma prepreg akasiyana aine mamiriro akasiyana ekugayiwa. Danho iri rakakosha pakuona kuti zvinhu zvakagadzikana uye kuti mashandiro azvo awedzere.

Kuburikidza nemamiriro ekunze anodziya zvakanyanya muovheni,kabhoni faibhauye resin matrix inoita zvese, zvichiita kuti pave nezvinhu zvakasimba zvinosanganiswa.

6. Kubviswa uye Kugadziriswa

Mushure mekubvisa firimu rekuputira reBOPP, chigadzirwa chakarapwa chinogona kubviswa. Firimu reBOPP rinogona kubviswa mushure mekurapwa. Kana zvichidikanwa, chitarisiko chinogona kunatsiridzwa kuburikidza nekukwesha nekupenda. Kuti runako ruwedzere kunaka, mamwe maitiro ekupedzisa akadai sekukwesha nekupenda anogona kuitwa.

Nguva yekutumira: Nyamavhuvhu-11-2025