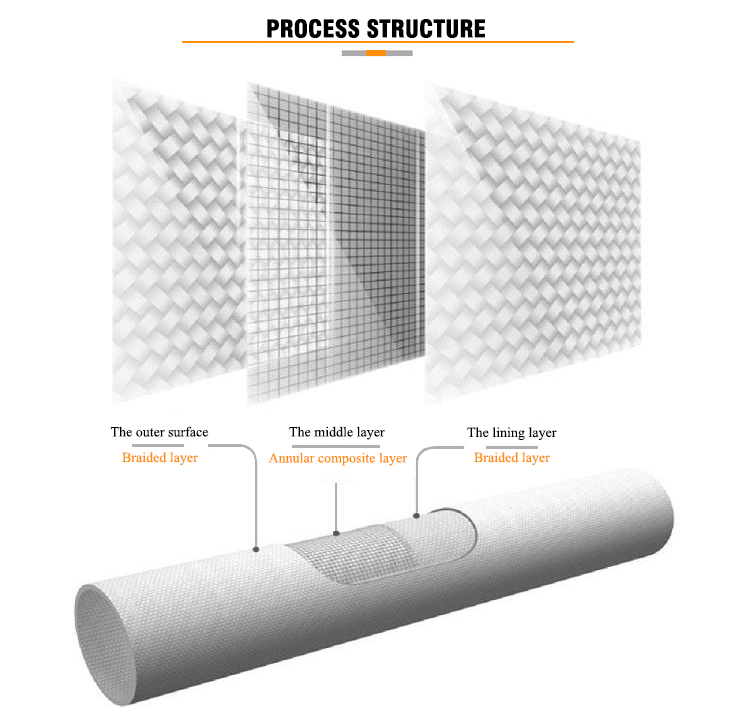

Pombi yeFRP rudzi rutsva rwezvinhu zvakasanganiswa, maitiro ayo ekugadzira anonyanya kuenderana nehuwandu hwakawanda hwe resin yegirazi fiber winding layer ne layer zvichienderana nemaitiro acho, Inogadzirwa mushure mekupiswa nekupisa kwakanyanya. Maumbirwo emadziro emapaipi eFRP ane musoro uye epamusoro, izvo zvinogona kupa basa rakazara kune zvinhu zvakaita segirazi fiber, resin uye curing agent, izvo zvisingangosviki chete pakusimba uye kuomarara kwakashandiswa, asiwo zvinovimbisa kugadzikana uye kuvimbika kwemapaipi eFRP.

Hunhu hwehunyanzvi

1.Kuenderera mberi kwekugadzira maitiro

Maitiro ekuumba anoenderera mberi akakamurwa kuita mhando nhatu: kuumba kwakaoma, kuumba kwakanyorova uye kuumba kwakaoma zvishoma zvichienderana nemamiriro emuviri uye emakemikari e resin matrix panguva yekuumba fiber. Kuumba kwakaoma kunosanganisira kushandisa shinda ye prepreg kana tepi yakagadziriswa prepreg, iyo inopiswa pamuchina wekuumba kuti iite nyoro kusvika pakuita viscous fluid uye yozosungirirwa pa core mold. Chinhu chikuru chemaitiro ekuumba kwakaoma ndechekuti inoshanda zvakanyanya uye kumhanya kwekuumba kunogona kusvika 100-200m/min; kuumba kwakanyorova kunosanganisira kuumba fiber bundle zvakananga (tape yakaita seshinda) pa mandrel pasi pekudzora kumanikidzwa mushure mekunyikwa muglue; Kuumba kwakaoma kunoda kuwedzera michina yekuomesa kuti ubvise solvent mushinda yakanyikwa mushure mekunge fiber yanyikwa mu core mold.

2.Kugadzirisa maitiro ekuumba mukati

Maitiro ekugadzirisa mukati inzira inoshanda yekuumba zvinhu zvinosanganisa fiber zvinogadzirwa nethermosetting. Chiumbwa chepakati chinodiwa pakugadzirisa mukati chimiro che cylindrical chisina chinhu, uye mativi ese akagadzirwa ne taper yakati kuti zvive nyore kubvisa. Pombi yesimbi isina chinhu inoiswa mukati me core mold, ndiko kuti, kupisa. Kune core tube, mugumo mumwe we core tube unovharwa, uye mumwe mugumo unovhurika semhepo inopinza. Maburi madiki anoparadzirwa pamadziro e core tube. Maburi madiki anogoverwa zvakaenzana muzvikamu zvina kubva ku axial section. Core mold inogona kutenderera yakatenderedza shaft, iyo iri nyore kutenderedzwa.

3. Kubvisa hurongwa

Kuti vakunde zvikanganiso zvakawanda zvekubviswa kwesimbi nemaoko, tambo yemazuva ano yekugadzira mapaipi esimbi yegirazi yakagadzira sisitimu yekubvisa otomatiki. Maumbirwo emuchina wekubvisa simbi anosanganisira mudziyo wekubvisa trolley, silinda inokiya, chibatiso chekubviswa kwesimbi, tsvimbo inotsigira uye sisitimu yepneumatic. Trolley yekubviswa kwesimbi inoshandiswa kusimbisa mold yepakati panguva yekumonera, uye silinda inokiyiwa panguva yekubviswa kwesimbi. Tsvimbo yepiston inodzoserwa shure, bhora resimbi rinosungirirwa rakasimudzwa parutivi rwechifukidziro chemashure rinoiswa pasi, sirinda inosunungurwa, uye tongs dzinobviswa dzinopedzisa maitiro ekusungirirwa kwesimbi kuburikidza nesimba rekutenderera kwespindle nesirinda, uye pakupedzisira kukiya sirinda netongs dzinobviswa. Paradzanisa muviri wechubhu kubva kumold yepakati nezvimwe zvishandiso kuti upedze maitiro ekubviswa kwesimbi.

Tarisiro yebudiriro yeramangwana

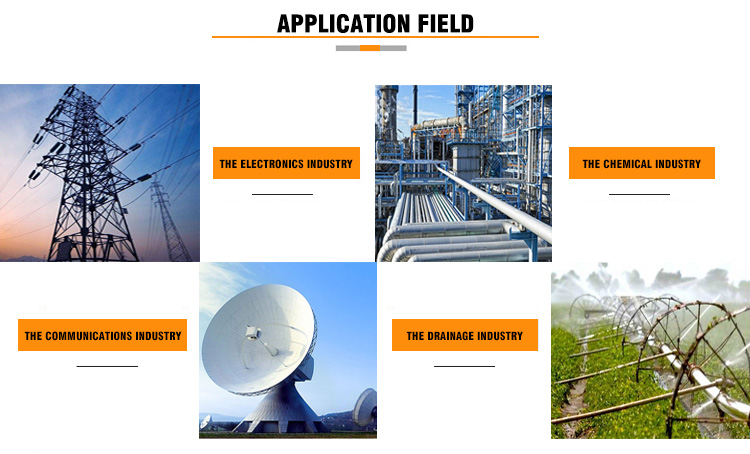

Munda wekushandisa chigadzirwa chakakura uye nzvimbo yakakura yemusika

Mapaipi eFRP akagadzirwa zvakanaka uye anogona kusangana nezvinodiwa zvekushandisa munzvimbo dzakawanda. Nzvimbo dzakajairika dzekushandisa dzinosanganisira kuvaka ngarava, kugadzira michina yeinjiniya yegungwa, petrochemical, gasi rechisikigo, simba remagetsi, mvura nedhiraini, simba renyukireya, nezvimwewo, uye kudiwa kwemusika kwakakura.

Nguva yekutumira: Kubvumbi-27-2021